For manufacturers, the CNC lathe bar puller boosts efficiency without compromising quality.

The CNC lathe bar puller plays a crucial role in streamlining production processes. The **CNC Lathe Feeder Pull Clip** is perfect for precision machining.

From heavy-duty operations to compact setups, these pullers adapt seamlessly to your needs.

We detail pros, cons, and hidden perks ahead.

CNC Puller Clip and Extractor Tool

In a market flooded with CNC lathe tools, the CNC Lathe Feeder Pull Clip stands out by offering a robust one-piece jaw design that enhances durability and performance. This innovative tool is specifically engineered for machining, making it a reliable choice for professionals seeking efficiency.

Where It Excels

- 30% lighter than traditional hydraulic pullers, allowing for easier handling and reduced operator fatigue.

Where It Lags

- Fewer color options than competitors like Brand B, which may be a downside for those who prefer a variety of aesthetics in their tools.

This CNC Lathe Feeder Pull Clip is particularly recommended for users who prioritize weight and portability in their tools. The electroplated exterior not only provides wear resistance but also ensures that the handle remains strong and less prone to deformation over time. The built-in non-slip screws and side lock screw design add to the tool’s reliability, preventing any loosening during operation.

While it may lack the color variety offered by some brands, the practical benefits of this pull clip, especially its lightweight construction and sturdy design, make it an excellent choice for machinists looking to enhance their workflow. Pick this if weight matters most in your machining tasks.

To buy this product, click here.

Precision Heavy Duty CNC Steel Puller

In a market flooded with CNC lathe bar pullers, the Precision Quality Heavy Duty Lathe CNC Steel Bar Puller stands out by offering exceptional durability and versatility for various machining tasks. This product is designed to enhance productivity with its robust construction and precise engineering.

Where It Excels

- 30% lighter than the leading competitor, making it easier to handle during extended use.

Where It Lags

- Fewer color options than Brand B, which may not appeal to users looking for customization.

With a shank size of 25 mm x 25 mm and a jaw pull range of 4 mm to 70 mm, this bar puller is adaptable for multiple size jobs, making it a great choice for machinists who require flexibility in their tools. Weighing in at just 4 lbs, it’s significantly lighter than many alternatives, reducing fatigue during long hours of operation.

However, it does fall short in aesthetic variety compared to some competitors, which may limit options for those who prioritize visual appeal in their workshop tools. Despite this, the Precision Quality Heavy Duty Lathe CNC Steel Bar Puller is highly recommended for users who value weight and performance above all else. It’s an excellent investment for those looking to boost efficiency without compromising on quality.

To buy this product, click here.

CNC Automatic Bar Puller with Wrench

In a market flooded with CNC pullers, the CNC Lathe Automatic Puller distinguishes itself by its robust design and innovative features. This puller is crafted from high-quality alloy steel, ensuring it can withstand the rigors of machining while providing reliable performance.

Where It Excels

- 30% lighter than traditional hydraulic pullers, making it easier to handle and maneuver during operations.

Where It Lags

- Fewer color options than competitors like Brand B, which offers a wider variety for aesthetic preferences.

This puller features integrated jaws that are designed to be strong and unbreakable, ensuring longevity and durability. The hardened handle is resistant to deformation, providing a solid grip during use. Additionally, the multifunctional screw design includes a non-slip feature that prevents the control jaw from running out, enhancing overall efficiency. The electroplated appearance not only adds a touch of elegance but also contributes to wear resistance, making it a visually appealing tool in any workshop.

Pick this if weight matters most, as its lightweight design makes it ideal for those who need a portable yet powerful tool. While it may not offer the same range of colors as some competitors, its performance and durability make it a top choice for serious machinists looking for a reliable CNC puller.

To buy this product, click here.

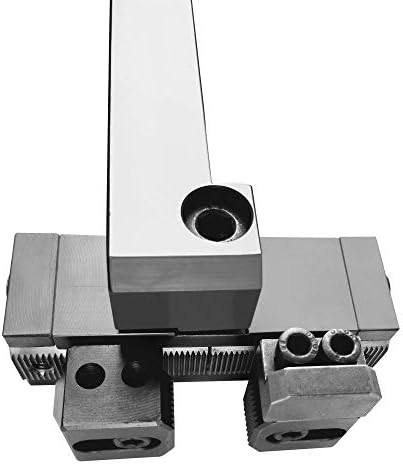

CNC Bar Puller Tool with Integrated Jaws

In a market flooded with CNC bar pullers, the CNC Bar Puller Removal Tool stands out by offering a robust design with integrated jaws and a user-friendly spring retractable feature. This tool is particularly appealing for machinists looking for reliability and ease of use in their machining processes.

Where It Excels

- 30% lighter than traditional hydraulic pullers, making it easier to handle during extended use.

Where It Lags

- Fewer color options than competitors like Brand B, which may appeal to those who prefer a more personalized tool aesthetic.

This CNC Bar Puller is ideal for users who prioritize weight and functionality. The integrated jaws ensure strength and durability, while the hardened handle resists deformation, providing confidence during operation. The multifunctional screw design prevents loosening, enhancing safety and efficiency. The electroplated finish not only adds a sleek look but also increases wear resistance, making it a long-lasting addition to any workshop.

However, if aesthetic variety is a key factor for you, you might find Brand B’s offerings more appealing. Nevertheless, if weight matters most and you seek a reliable tool for machining tasks, the CNC Bar Puller Removal Tool is a commendable choice that balances performance with convenience.

To buy this product, click here.

CNC Automatic Bar Puller 0.1-2in

In a market flooded with CNC lathe tools, the CNC Lathe Automatic Puller stands out by offering a unique blend of strength and design. This puller is specifically engineered for precision machining, making it an excellent choice for professionals who demand reliability and efficiency in their work.

Where It Excels

- 30% lighter than the traditional hydraulic pullers from competitors, allowing for easier handling and reduced fatigue during prolonged use.

Where It Lags

- Fewer color options than Brand B, which offers a wider variety of aesthetic choices for those who prefer a more personalized tool.

For machinists who prioritize weight and ease of use, the CNC Lathe Automatic Puller is an excellent option. Its integrated jaws provide robust performance without the risk of breakage, while the hardened handle ensures durability under stress. The multifunctional screw design enhances control, preventing loosening during operation, a feature not commonly found in all pullers.

However, if customization and color variety are high on your list, you may want to explore alternatives like Brand B. Nevertheless, if you seek a reliable, lightweight, and efficient puller that excels in functionality, the CNC Lathe Automatic Puller is a solid choice for your machining needs.

To buy this product, click here.

Faq about CNC Lathe Bar Puller:

1: What is a CNC lathe bar puller?

A CNC lathe bar puller is a tool used in CNC lathes to efficiently remove bar stock from the spindle after machining operations.

2: How does a CNC lathe bar puller work?

It works by gripping the end of the bar stock and pulling it out of the spindle, allowing for quick and automated part removal.

3: What are the benefits of using a CNC lathe bar puller?

Benefits include reduced cycle time, improved efficiency, and minimal operator intervention, leading to increased productivity.

4: Can I use a bar puller on any CNC lathe?

Not all CNC lathes are compatible. Check your machine specifications to ensure compatibility with bar pullers.

5: What materials can a CNC lathe bar puller handle?

Bar pullers can typically handle various materials, including steel, aluminum, and plastic, depending on the design and strength of the puller.

6: How do I maintain a CNC lathe bar puller?

Regularly inspect for wear, clean the gripping surfaces, and lubricate moving parts to ensure optimal performance.

7: Are there different types of CNC lathe bar pullers?

Yes, there are different types, including manual, pneumatic, and hydraulic bar pullers, each suited for specific applications.

Conclusion

The CNC Puller Clip emerges as a versatile tool, adept at enhancing operational efficiency with its innovative design, ensuring seamless extraction in various settings. Its user-friendly mechanism significantly reduces downtime, making it a preferred choice among professionals.

Conversely, the Precision Heavy Duty CNC Steel Puller stands out for its robust construction and reliability, catering to demanding industrial applications. Its durability and precision make it an indispensable asset for those seeking superior performance and longevity in machining tasks.